AUTOCLAVE DEFINATION, OPERATING AND WORKINMG PRINCIPLE | MVTEX

INTRODUCTION

In this blog you will discover a picture and details for how to use both of these equipment’s but before that we will understand roughly .

Autoclaves play a crucial role in laboratories, medical facilities, and various industries by sterilizing equipment, materials, and instruments through high-pressure steam. There are several blogs and resources dedicated to autoclaves and sterilization techniques. Here’s a glimpse into what you might find in such a blog:

- Autoclave Tips and Tricks: This blog focuses on practical advice for operating autoclaves efficiently. It might cover topics such as:

- Proper Usage: How to load items correctly for effective sterilization.

- Maintenance: Regular maintenance schedules and tips for keeping autoclaves in optimal condition.

- Troubleshooting: Common issues and their solutions.

- Sterilization Techniques: Different sterilization cycles and when to use them.

- Innovations and Technology: Discussions on the latest advancements in autoclave technology and how these innovations improve efficiency, reduce sterilization times, or enhance safety features.

- Industry Updates: Insights into how autoclaves are used across various industries—medical, research, pharmaceuticals, and more. This might include compliance updates, regulations, and best practices specific to each sector.

- Case Studies and Reviews: Real-world examples of how autoclaves have been implemented successfully in different settings, along with reviews of different autoclave models, their pros and cons, and user experiences.

- Sterilization Methods: Besides autoclaving, discussions about other sterilization methods, their advantages, limitations, and comparative analyses might be featured. These could include chemical sterilization, radiation, or other heat-based methods.

- FEATURES

Autoclaves, used for sterilization in various industries including medicine, laboratories, and manufacturing, come with various features that ensure efficient and effective sterilization processes. Here are some key features commonly found in autoclaves:

- Temperature and Pressure Controls: Autoclaves maintain specific temperatures and pressures necessary for sterilization. They allow users to set and control these parameters based on the materials being sterilized.

- Sterilization Cycles: Different sterilization cycles are available (e.g., gravity, pre-vacuum, etc.) to accommodate various materials, ensuring thorough sterilization without damaging the items.

- Chamber and Loading Capacity: Autoclaves come in various sizes with different chamber capacities. They are designed to accommodate different loads of instruments or materials for sterilization.

- Safety Features: These include interlocking systems preventing the door from opening when the chamber is pressurized or the temperature is high, ensuring user safety.

- Monitoring and Controls: Modern autoclaves often come equipped with digital displays, control panels, and programmable features for easy monitoring and adjustment of sterilization parameters.

- Drying Cycles: Some autoclaves have post-sterilization drying cycles to remove excess moisture from sterilized items.

- Data Logging and Documentation: Advanced autoclaves may include features for data logging, allowing users to track and document sterilization parameters for quality control and compliance purposes.

- Steam Generation and Release: They have mechanisms for steam generation and proper release to ensure uniform distribution within the chamber for effective sterilization.

- Materials and Construction: Autoclaves are constructed using materials compatible with high temperatures and pressures, ensuring durability and safety during operation.

- Maintenance and Self-Diagnostics: Some autoclaves offer self-diagnostic features and reminders for maintenance tasks, ensuring proper functionality and longevity of the equipment.

- Compatibility with Regulations: Autoclaves are designed to meet specific industry standards and regulations regarding sterilization and equipment safety.

These features may vary depending on the type of autoclave (e.g., benchtop, vertical, horizontal, etc.) and the intended use in different industries. However, these elements collectively ensure the efficient and reliable sterilization of various items, contributing to safety and quality control in diverse settings.

- TYPES OF AUTOCLAVES

Autoclaves come in various types and configurations, each tailored for specific purposes and settings. Here are some common types:

- Gravity Autoclaves: These are the most basic type and work by displacing air in the chamber with steam. Gravity autoclaves are suitable for simple sterilization processes but might not be ideal for heat and moisture-sensitive materials.

- Pre-Vacuum Autoclaves: These autoclaves use a series of vacuum pulses before the sterilization cycle to remove air from the chamber, ensuring better steam penetration. They’re effective for sterilizing porous materials and can be gentler on delicate instruments.

- Steam Flush Pressure Pulse (SFPP) Autoclaves: These combine the benefits of pre-vacuum and gravity autoclaves, using steam flushes and pressure pulses for effective air removal and penetration. SFPP autoclaves are suitable for a wide range of materials and sterilization needs.

- Pass-Through Autoclaves: These are designed with double doors to allow materials to be loaded from one side and removed from the other. They are often used in cleanroom or laboratory settings to prevent contamination.

- Benchtop Autoclaves: Smaller in size, these autoclaves are suitable for smaller labs, dental practices, or clinics where space is limited. They’re typically used for sterilizing instruments, glassware, and small amounts of materials.

- Vertical Autoclaves: These have a vertical chamber orientation, making them suitable for labs with limited floor space. They often have a taller chamber and are used for sterilizing liquids, media, and taller instruments.

- Horizontal Autoclaves: Designed with a horizontal chamber, these autoclaves are suitable for sterilizing larger volumes of materials, such as laboratory glassware, surgical instruments, and medical waste.

- Vacuum Autoclaves: Primarily used in medical and healthcare settings, these autoclaves use vacuum technology to sterilize materials at lower temperatures, which can be less damaging to heat-sensitive items.

Each type of autoclave has its advantages and is suited for different applications and industries. The choice of autoclave depends on factors such as the types of materials to be sterilized, the volume of items, space availability, and specific sterilization requirements.

- ROLE OF AUTOCLAVE IN RESEARCH LAB

Autoclaves play a vital role in research settings across various fields. Here’s how they’re commonly used:

- Sterilization of Equipment: Autoclaves are crucial for sterilizing laboratory equipment, glassware, and tools before experiments to prevent contamination and ensure accurate results.

- Media Preparation: In microbiology and biotechnology research, autoclaves are used to sterilize culture media, agar plates, and other growth mediums to provide aseptic conditions for growing microorganisms.

- Waste Sterilization: Autoclaves sterilize biohazardous waste, such as used petri dishes, contaminated materials, or infectious samples, ensuring safe disposal and compliance with regulations.

- Sample Sterilization: Researchers sterilize samples, instruments, and containers for cell culture, DNA manipulation, or protein studies to maintain sterile conditions and prevent cross-contamination.

- Lab Decontamination: Autoclaves can decontaminate lab coats, pipettes, and other reusable items, reducing the risk of spreading contaminants between experiments or different areas of the lab.

- Animal Facility Use: In animal research facilities, autoclaves sterilize bedding, cages, and surgical instruments to maintain hygiene and prevent the spread of diseases among research animals.

- Quality Control: Autoclaves aid in quality control by ensuring that materials used in experiments are free from microbial contamination, contributing to reliable and reproducible research outcomes.

Researchers across disciplines, from biology and chemistry to medicine and environmental science, rely on autoclaves to create sterile environments essential for accurate experimentation, analysis, and the advancement of scientific knowledge. These machines are indispensable tools for maintaining the integrity and reliability of research findings by minimizing the risk of contamination.

- WORKING OF AUTOCLAVE

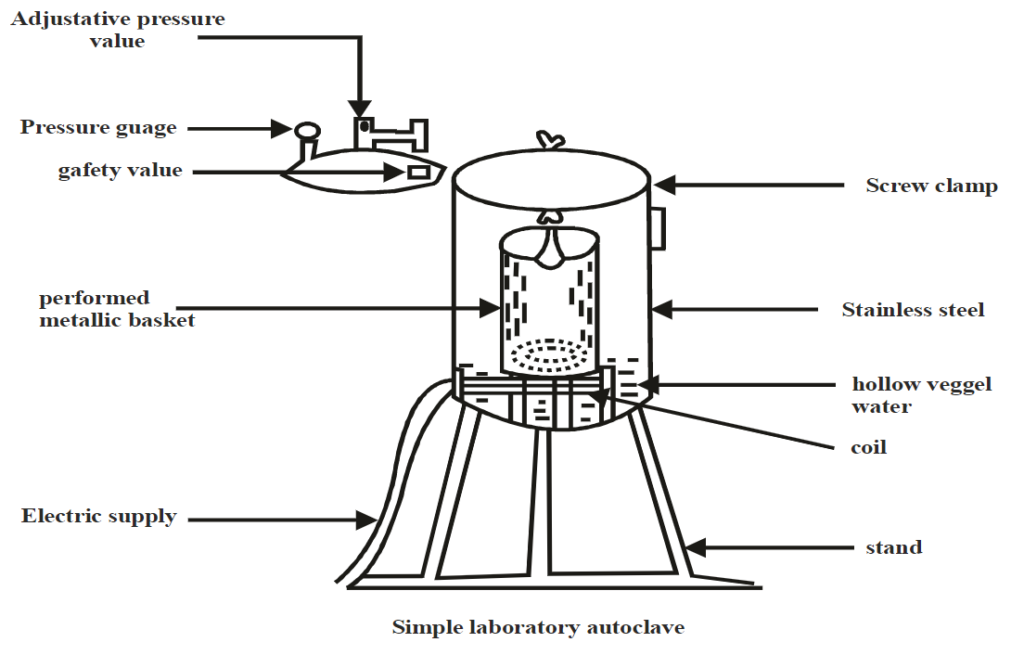

The working principle of an autoclave revolves around high-pressure steam to achieve sterilization. Here’s a breakdown of how autoclaves typically operate:

- Chamber Loading: Items to be sterilized are loaded into the autoclave chamber, ensuring they are arranged in a way that allows steam to penetrate freely.

- Sealing and Pressurization: Once the chamber is loaded and the door is securely sealed, the autoclave begins the sterilization cycle. The chamber is sealed to prevent steam from escaping.

- Air Removal: In autoclaves with vacuum systems, air is removed from the chamber through vacuum pulses. This step ensures that steam can penetrate effectively for proper sterilization.

- Steam Injection: Water inside the autoclave is heated to produce high-pressure steam. This steam is then injected into the chamber, increasing the temperature and pressure within.

- Sterilization Phase: The chamber temperature and pressure are maintained at specific levels for a predetermined time, depending on the materials being sterilized. Typically, the temperature reaches around 121°C (250°F) to 134°C (273°F) with pressures of 15-30 psi.

- Drying Phase (optional): Some autoclaves include a drying phase where excess moisture is removed from the sterilized items, ensuring they are dry when removed from the chamber.

- Depressurization: After the sterilization phase, the steam supply is halted, and the chamber pressure is gradually reduced to atmospheric pressure. This step prevents sudden temperature and pressure changes that could damage sterilized items.

- Cooling Phase: Once the pressure has normalized, the autoclave gradually cools down, allowing safe removal of the sterilized items.

- Cycle Completion: The sterilization cycle completes, and the autoclave indicates that items can be safely removed.

The combination of high temperature, pressure, and exposure time to steam is what effectively kills microorganisms, spores, and other contaminants, ensuring thorough sterilization of the items within the autoclave chamber. Autoclaves are essential tools for maintaining sterile conditions in various industries, including healthcare, laboratories, pharmaceuticals, and research facilities.